Our state-of-the-art SMD circuit board production, which is optimized for flexibility, our own high-performance plastic injection molding shop, our partially automated cable harness production, 30 assembly workstations and our in-house packaging line enable short delivery times and flexible order processing – especially for small to medium-sized series.

Birth of Gaslock GmbH

To the specialist for technology products

INDY-CATOR®

GASLEVEL®

Production

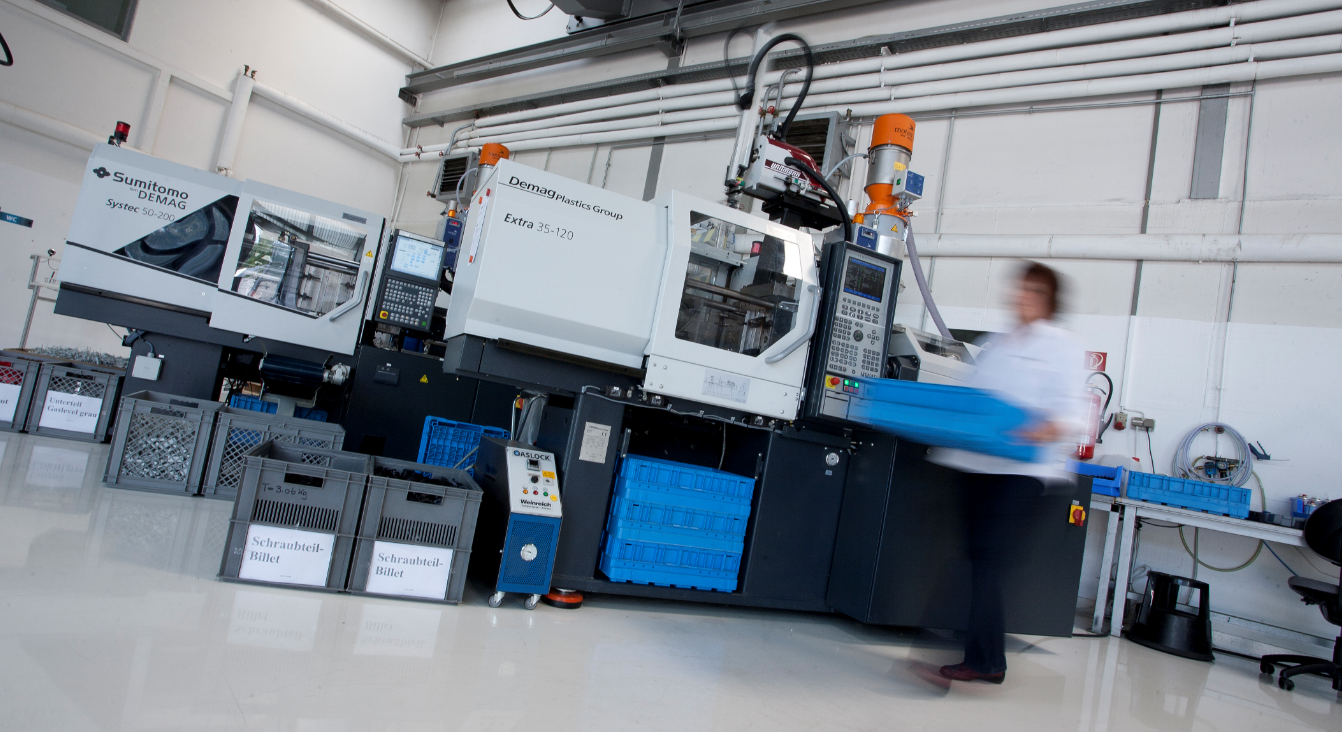

MODERN PRODUCTION PLANTS

IN ISERLOHN

Our production facilities for lockable fuel caps, oil dipsticks, fuel level indicators, gear indicators and gas level indicators are state-of-the-art and partly developed in-house. In this way, we ensure high product quality, as demonstrated, for example, by the long-standing business relationship with Harley-Davidson that has existed since Gaslock was founded.

Electronic modules

Our solder paste printers, SMD technology (component placers) and vapor phase soldering machines, which are optimized for flexibility, enable us to produce boards (printed circuit boards) of the highest quality, low reject rates and highly flexible order processing.

Some of our PCBs and sensors are overmolded with thermoplastics on our injection molding machines. Here we have gained a lot of experience in the so-called “over-molding”.

Manual assembly

In final assembly, our well-trained specialists work at ergonomically designed workstations. Depending on the product, we assemble in island assemblies or individual assembly lines. Our packaging line is flexible in use.

Engravings, inscriptions

Whether stainless steel, aluminum, brass or plastic – we mark (label) our products at the end of the production process by laser engraving and pad printing.

Interested in more information? We will gladly inform you!

TANK CAPS AND LEVEL GAUGES

Since 1998, we have been developing and producing lockable tank caps for Harley-Davidson motorcycles and gear indicators for the automotive industry since 2005. We quickly expanded our product portfolio and developed level indicators for oil, gasoline, gas and water. More than 15 years after the foundation of our company, we have comprehensive technical competences:

- As a medium-sized company, we are specialists in the production of complex mechanics (e.g. tank cap closures) and level indicators in small and medium-sized series.

- At our site in Iserlohn, Germany, we have modern production facilities and well-trained specialists. We ensure our high product quality "Made in Germany" by a mature quality management system.

- Through many years of cooperation with Harley-Davidson and the automotive industry, we know what is important for technical products with high emotionality, also visually and haptically.

- Led by founder and master motorcycle mechanic Jörg Lienenkamp, we master the art of craftsmanship with attention to detail.

Cart is empty

Cart is empty